Our comprehensive range of sheet metal processing equipment caters to diverse industries including kitchen furniture, construction, and medical sectors. With a wide array of functions available, you can find the ideal processing equipment tailored to your specific industry requirements and market demands. We offer high-quality equipment and dedicated service support at competitive prices to ensure your operational needs are met efficiently and effectively.

Built for your Industry

We Provide Appropriate Manufacturing Solutions

Our sheet metalworking equipment caters to various applications across industries, including kitchen furniture, facade & metal cladding, medical equipment, steel pole, elevator, etc.

Applications

From bending and cutting to stamping, grooving, drilling, and leveling, we offer a comprehensive range of sheet metal processing equipment tailored to meet your diverse manufacturing requirements.

Sheet Metal Bending

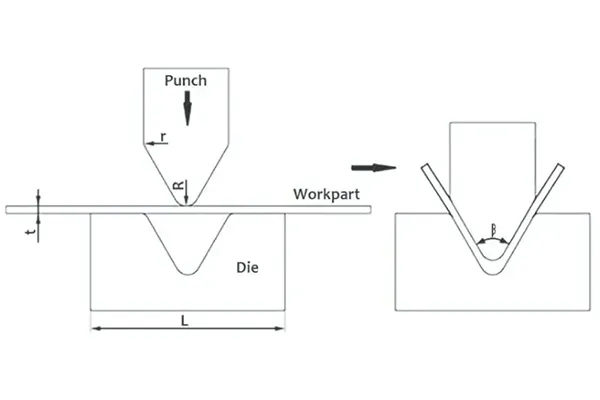

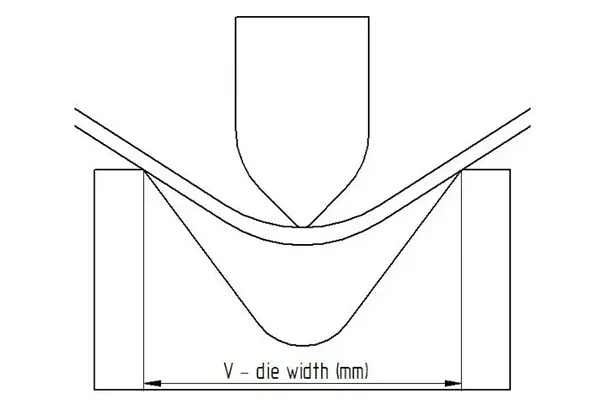

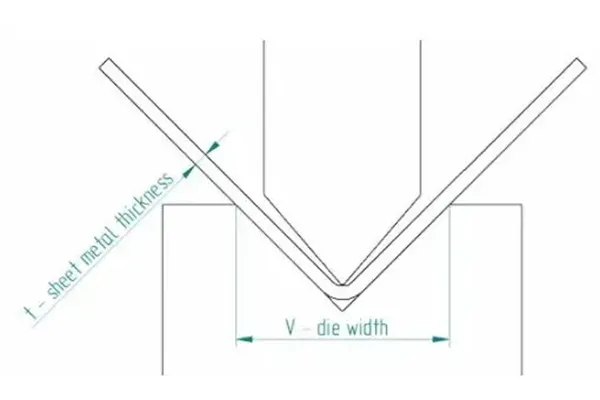

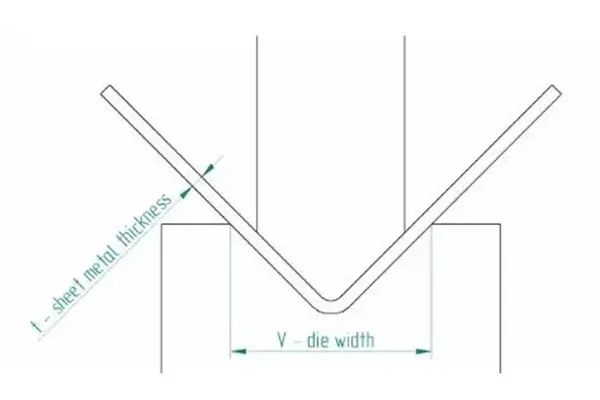

Sheet metal bending, also known as crimping or die bending, involves deforming a material into an angular shape by applying force. Common types of bending include V-bending, priming, air bending, casting, and U-bending.

Recommended product

-

- Press Brakes Press brakes are essential tools for forming sheet metal, characterized primarily by their bending capacity and metal gauge compatibility. View More

Sheet Metal Cutting

Sheet metal cutting encompasses various methods such as flame cutting, plasma cutting, laser cutting, punching, blanking, and slotting to cut, shear, and form metal materials. It's applicable to a range of materials including steel, aluminum, copper, stainless steel, galvanized steel sheet, and cold-rolled sheet.

Recommended product

-

- Hydraulic Shears Our hydraulic shears are engineered for optimal performance in cutting carbon steel plates, stainless steel, galvanized sheets, and other metals, serving as a fundamental tool in sheet metal processing. View More

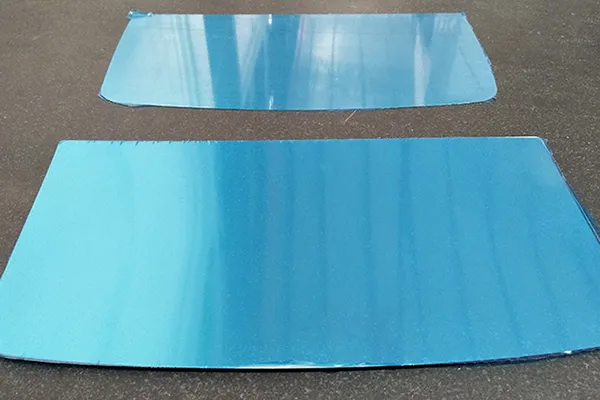

Sheet Metal Rolling/Round Bending

Sheet metal rolling or round bending shapes a metal workpiece into a round or curved form to meet specific requirements. Various bending methods are employed, including plate bending machines, hydraulic 2-roll/3-roll/4-roll plate bending machines, and profile bending machines.

Recommended product

Sheet Metal Stamping

Sheet metal stamping transforms coil or sheet metal into required workpieces using punches and dies. It involves the use of pneumatic presses, mechanical presses, servo presses, and hydraulic presses. The choice of equipment and punch & die sets depends on specific needs and preferences.

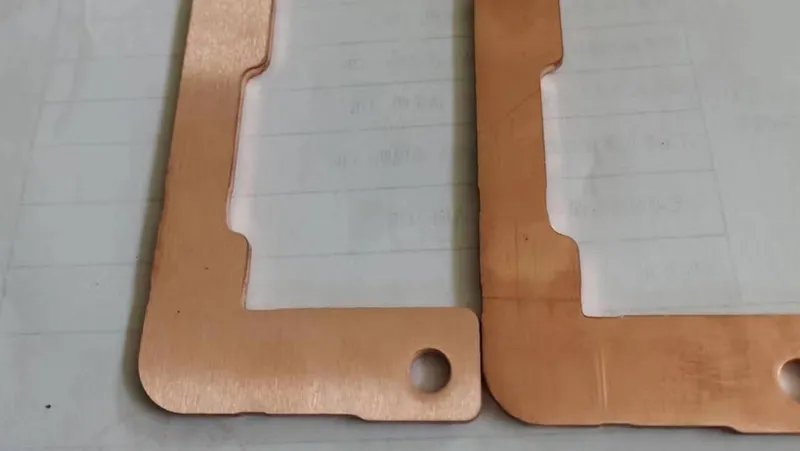

Sheet Metal Grooving

Sheet metal grooving creates grooves on metal sheets to facilitate folding into tight radii. This process is widely used in the elevator industry, high decoration industry, curtain walls, among others. Materials such as stainless steel, iron plate, and copper plate are commonly grooved.

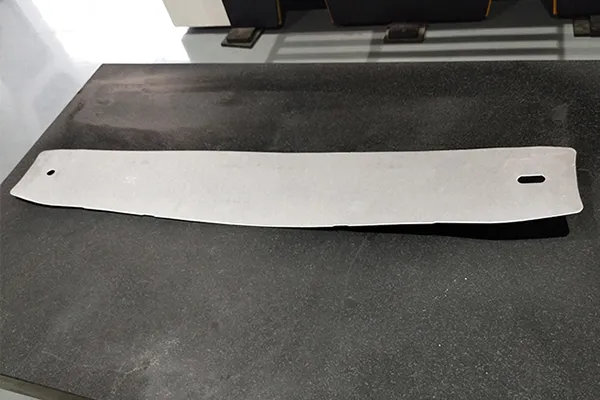

Sheet Metal Leveling

Sheet metal leveling corrects shape deviation, warping, or bending to ensure final products meet required standards. It involves methods like hammer and flame leveling, plate bending machine leveling, hydraulic press leveling, and roller leveling.

Recommended product

-

- Precision Leveler A precision leveler is a machine used in metalworking to flatten or straighten metal sheets or coils with high precision. View More

Sheet Metal Deburring

Sheet metal deburring removes tiny protruding edges formed during cutting processes. Common deburring methods include manual deburring and automatic deburring with slag hammers, abrasive belts, etc. Different burr classifications include Poisson burr, rollover burr, and breakout burr.

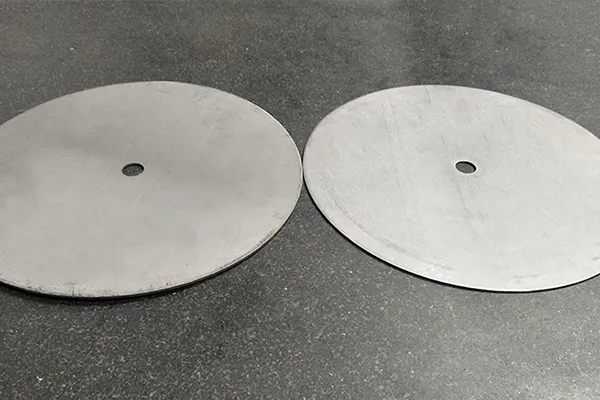

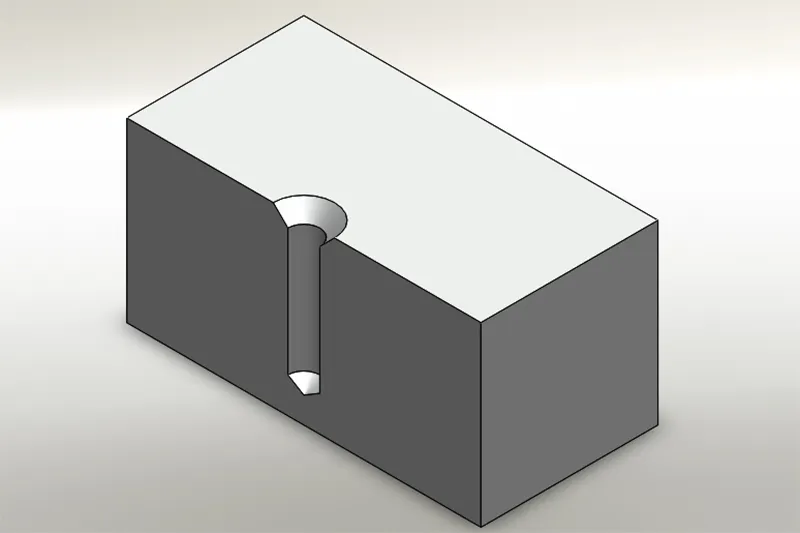

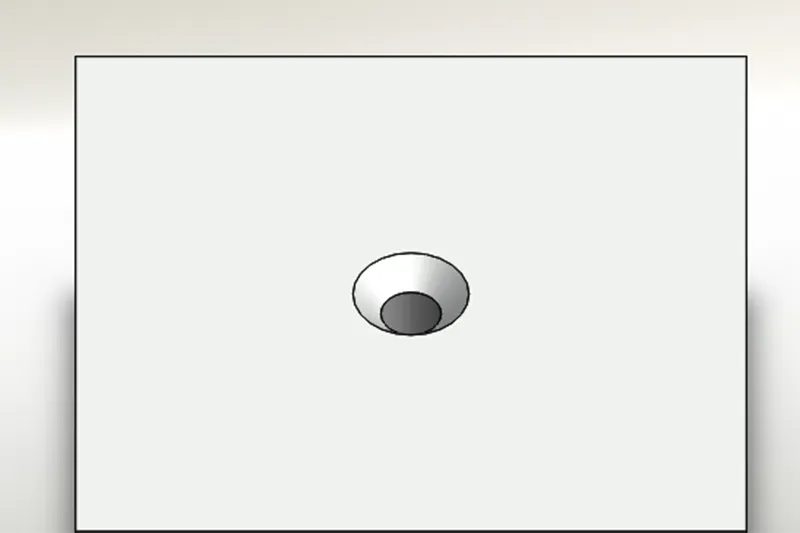

Sheet Metal Drilling

Sheet metal drilling creates holes by rotating cutters and exerting pressure on the workpiece. It's performed using various drilling machines such as manual drilling machines, sensitive drilling machines, and multi-axis drilling machines. Operations include drilling, reaming, boring, tapping, etc.